Wear Resistant Materials & Solutions

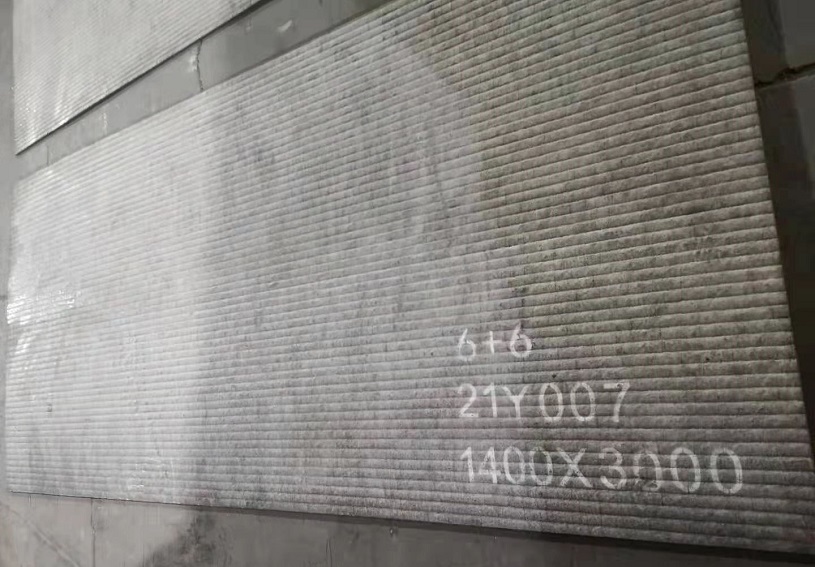

Smooth and Crack-free Chrome Carbide Overlay Plate

SMOOTH CCO (Chrome Carbide Overlay) is a special clad steel plate manufactured by a special overlay weld depositing, ultra abrasion resisting alloy on the base metal made of mild steel plate. Our special automatic welding method has made it possible to manufacture very hard and high-quality plates which are practically free from cracks and welding beads.

Features

➊The chief advantage of SMOOTH CCO is its excellent abrasion resistance, especially the precipitation of various kinds of carbide has made it possible to be used for the parts which require strong abrasion wear, erosion wear, and impact toughness.

➋The surface of SMOOTH CCO is smooth without any practical irregularity, cracks and welding beads are eliminated to the inconceivable level that the conventional CCO could not achieve.

➌The SMOOTH CCO has a uniform chemical composition and hardness(60-64HRC) throughout the thickness, hardness difference throughout thickness normally below 3 Rockwell units

➍1.5-4 times service life when compared to conventional overlay plates.

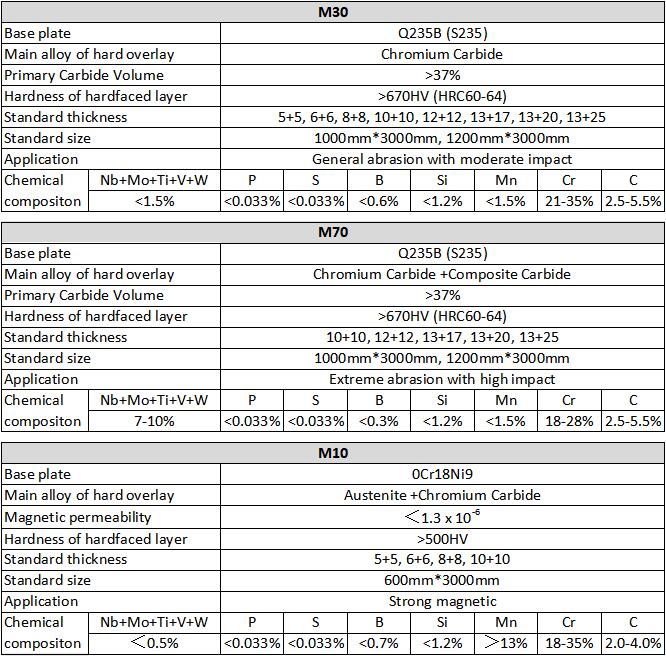

The following 3 types of SMOOTH CCO are available from CS Wear:

M30

M30 is developed for regular wear applications, it has excellent wear resistance and can take moderate impact, the plate is very flat and free of cracks, which results in lower friction and fewer hang-ups when handling bulk materials, the chromium carbide particles are well and uniformly distributed in the overlay layer, which improves the strength of the plate, the plate maintains good toughness when increasing the hardness to 59-64HRC, thus making the plate possible to achieve more hardness, good abrasion resistance, and decent impact toughness.

M70

In addition to Cr, W/Nb/Ti/V/Mo and other precious metal elements are added to the overlay layer to make the metal structure more delicate, the M70 plate has a considerable amount of composite carbide in addition to Cr carbide which made it has particular stronger abrasion resistance and impact resistance, At the same time, the carbide dispersion distribution technology is applied to achieve a uniform distribution of the multifold carbides, making the M70 body strong and powerful.

M10

M10 is a non-magnetic steel wear-resistant plate specially developed for a strong magnetic working environment, a overlay layer with low magnetic permeability is deposited on the surface of stainless steel or non-magnetic steel, so the wear plate will not be impacted in a strong magnetic environment.

M10 is used in magnetic separators, iron separators, iron removers, and other magnetic separation equipment, providing 5 times the service life of 304 stainless steel, the M10 is also very flat and free of cracks.

Standard sizes, thicknesses, and technical specification

Microstructure

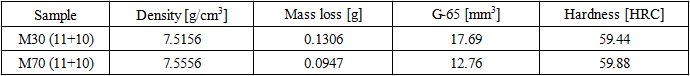

Abrasion Resistance

It is considered that the SMOOTH CCO may be mainly abraded by grinding and erosion caused by slipping of materials, the below test result (measured by loss weight in gram) of our SMOOTH CCO from ASTM-G65-4 for reference:

Mass loss of M30<0.15g

Mass loss of M70<0.11g

The test result of Typical thickness:

Application

The SMOOTH CCO can be applied to various industrial fields such as cement, iron manufacturing, coke, coal, mining, civil engineering and quarrying, casting, etc.

Equipment to which SMOOTH CCO is applied: Various kinds of chutes, hoppers, fans, screens, crushers, grizzly bars, dampers, mixers, cyclones, etc

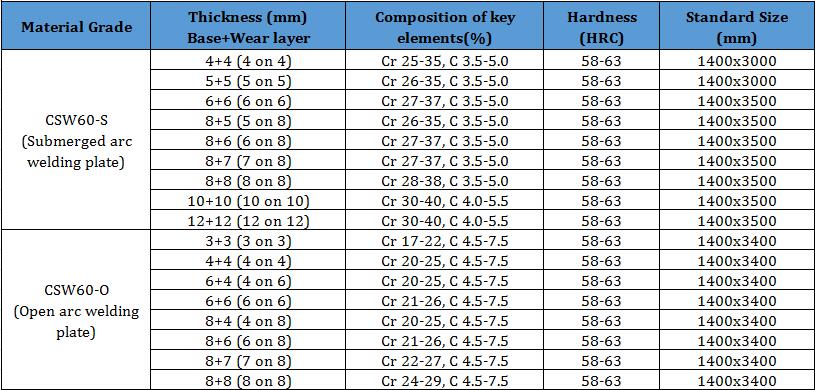

Regular Chrome Carbide Overlay Plate

Chromium Carbide Overlay(CCO) is chromium carbide composite cladding that is fusion bonded to a backing material, which is well known for being one of the most abrasive resistant material. The overlay material is an austenitic chromium carbide iron deposited by a submerged arc welding or open arc welding process, the microstructure consists of primary Cr7C3 carbides in a carbide austenite eutectic matrix. The high abrasion resistance is provided by the hard chromium carbides that protect the matrix from abrasive wear. The standard backing material for CCO is mild steel, the backing plate acts as a ductile base, which offers good impact resistance & toughness and allows CCO to be formed and shaped without damage to the overlay material.

Standard sizes:

Features:

❶ Other sizes and thicknesses are also available upon request

❷ Volume percent of Cr7C3 in Microstructure is more than 35%

❸ Hardness as high as HRC 58-63, hardness equally distributed

❹ High abrasive resistance, outlast quench and tempered steel (400BHN Q&T plate) by 5-6 times in high abrasion applications

❺ Thickness of overlay material equally distributed, tolerance below 0.5 mm

❻ Flatness below ±3mm/m

❼ Plates can be cut to other sizes & shapes, studs, holes can be added or machined upon request.

Welding:

The base material can be welded with standard mild steel or low hydrogen welding consumables with no pre-heating required. However, care should be taken to avoid contacting the overlay material.

Cutting

Plasma cutting is the recommended method for cutting CCO plate. It is preferable to cut CCO from the backing plate side to ensure a clean edge and to prevent carbide contamination.

Copyright © CS Wear Resistant Material Co., Limited . All rights reserved.