Wear Resistant Materials & Solutions

Laminated wear blocks are unique and excellent, in that they have extremely wear-resistant quality and they are weldable, this material is a combination of high chrome white iron metallurgically bonded to a mild steel backing plate through a vacuum brazing process, the high chromium white iron has an extremely high hardness of brinell 700HB (63HRC) and mild steel backing plate makes them weldable and good impact resistance. Typical products including chocky bar, wear button, wear strips, wear plate, shredder hammer tips, and much more other wear blocks, they are available both in standard shapes and also customized sizes.

Advantages:

❶ Longer wear life when compared to conventional materials like AR quenched and tempered plates & clad plates

❷ Mild steel backing offers good weldability, machinability, and impact resistance, easy to install and maintain, can be welded in place, through-bolted, stud bolted, drilled, tapped, keyed.

❸ Chrome saturated white cast iron offers high wear and abrasion resistance, enable your equipment to work in harsh working conditions

❹ Increased production, reduce downtime and maintenance costs

Typical products:

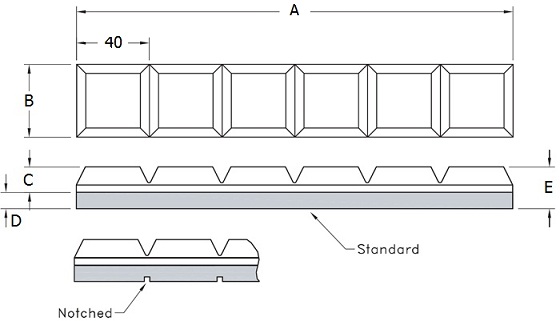

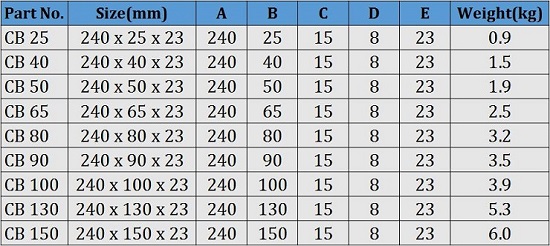

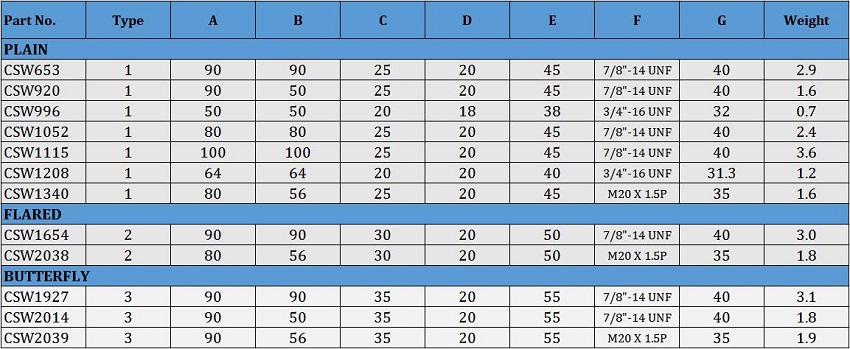

CHOCKY BAR

Chocky bar is one of the typical materials of Laminated wear blocks, which is a combination of high chrome white iron metallurgically bonded to a mild steel backing plate. The high chromium white iron offers an extremely high hardness of brinell 700HB (63HRC) and mild steel backing plate offers good impact resistance and weldability. Also the "V-groove" design allows chocky bars to be bent around a radius or separated to changed length requirement needed.

Chocky bars can be welded onto inside or outside curved surfaces to provide an extra level of protection for wear and impact applications. Used extensively for wear protection on buckets, excavators, dragline machines or for lining chutes and rock box edges.

We have two types of chocky bars for option base on it's backing plate whether standard or notched, Notched chocky bars are easier to cut, bent and shaped to suit contoured surfaces.

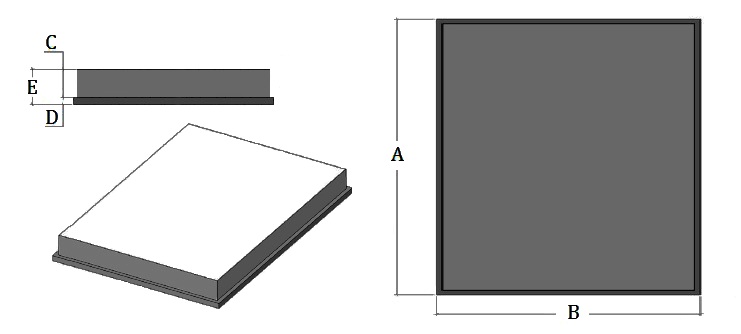

LAMINATED WEAR PLATE

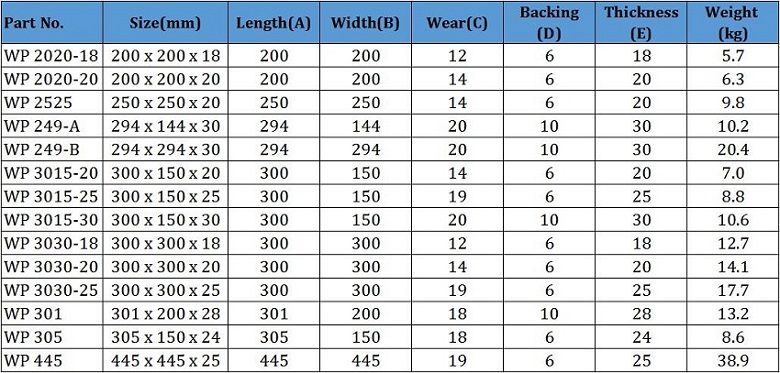

Laminated wear plate is also a combination of Chrome white iron wear casting vacuum brazed onto mild steel base, with Hardness of 63HRC/700BHN, the wear surface is smooth and flat, wear life normally 2 times longer than clad plate and 6 times longer than AR 400 steel plate.

Suitable for use in chutes, hoppers, bins, liners, impact walls, rock boxes and a variety of other applications. Very easy to use, no pre or post heating when welding. Weld-on or bolt-on studs or bolt holes can be easily added upon customer’s requests.

CS Wear Laminated wear plates can make with different shapes and sizes. In order to guarantee bonding area and good bonding quality, we normally set a limit on sizes of wear plate, any size combination is available within below ranges:

Thickness: normally above 1/2” (12mm)

Width: normally below 40” (1000mm)

Length: normally below 40” (1000mm)

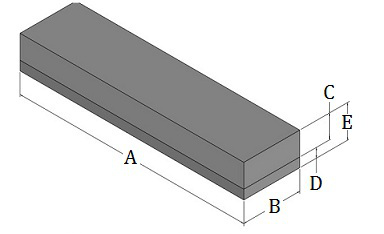

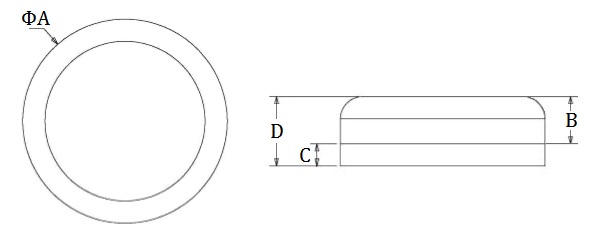

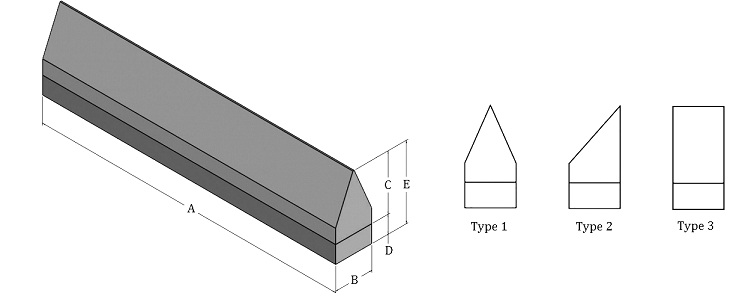

WEAR BAR

Wear Bars are the utility item of the CS Wear product line. They are suitable for both fixed & mobile applications

With a wide selection of width, thicknesses, and shapes for option. Other sizes can be customized to meet your specific application. Weld-on or bolt-on studs or bolt holes can be easily added upon customer’s requests.

Common applications are protection of inner & external wall of heavy earth moving buckets, chute & lip protection, build up points in impact zones, and much more other applications.

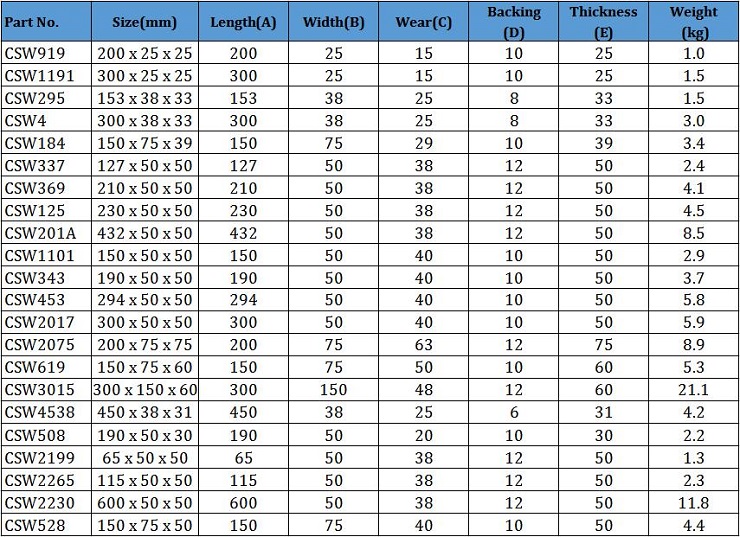

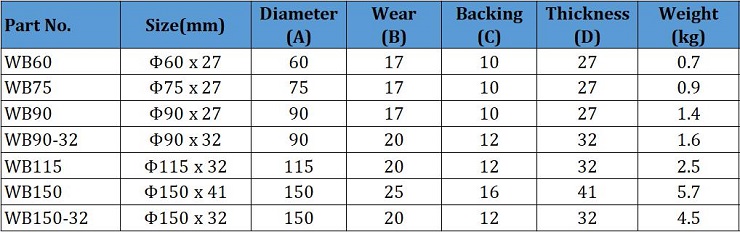

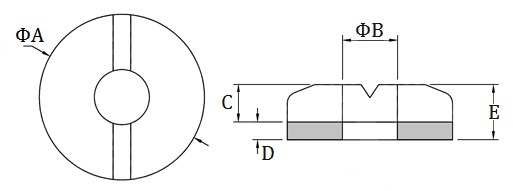

WEAR BUTTONS & DONUTS

Wear Buttons & Donuts are the perfect material for wear protection of smaller areas, easy to install with no pre or post heating required, requires less welding time and material, The Donuts also offers flexible options with internal and external welding, Variability in size, Available in diameters from 60mm to 150mm.

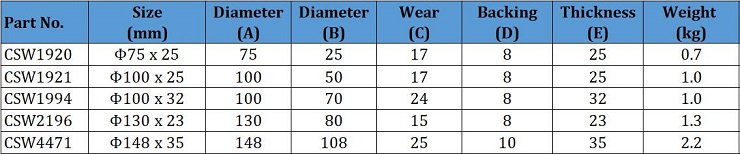

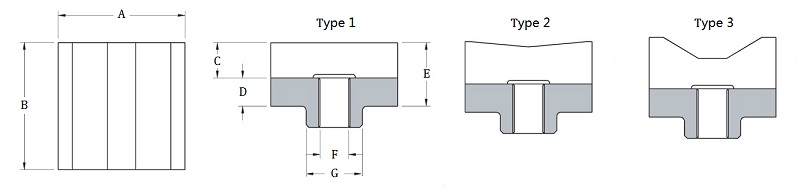

SUGAR MILL WEAR BLOCKS

CS Wear sugar mills wear blocks are designed specially for the sugar industry, which is the most cost effective alternative to expensive, labour intensive

hard-facing methods.

❶ SHREDDER HAMMER TIPS

CS Wear 700BHN Hammer Tips are far superior to standard Q&T wear tips and hardfacing,

Machined steel base allows for quick & easy installation through bolt on or weld on

Cost effective as compared to hard facing

Superior edge retention & sharpness

No need to rebuild edges, tips can be rotated for maximum wear life

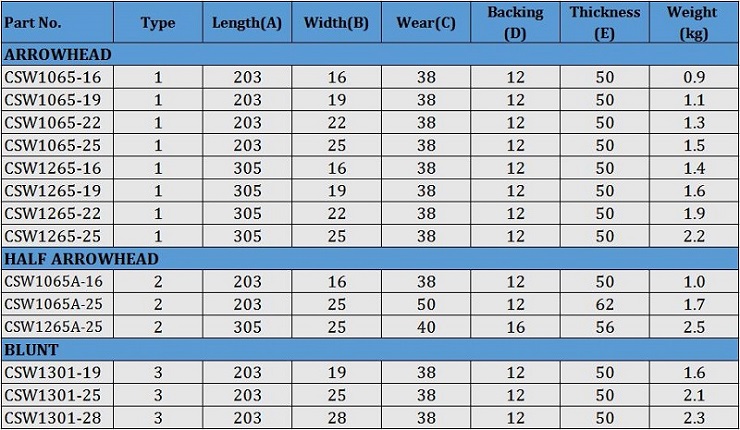

❷ KNIFE EDGES & CANE KNIFE CHOPPERS

CS Wear 700BHN Knife Edges are far superior to Q&T knife edges offering greater wear life

Cost effective compared to hard facing

Superior edge retention & sharpness

Easy to install, maintain & replace

Will provide increased production & cutting efficiency

Arrowhead, Half Arrowhead & Blunt Styles available for option, other shapes and sizes also available upon customer’s request.

Applications:

Laminated wear blocks are extensively used for wear protection in the Mining industry, Quarry industry, Cement industry, Dredging industry, Recycling industry and etc

Copyright © CS Wear Resistant Material Co., Limited . All rights reserved.